Choosing the Right Location

Consider Access and Convenience

When it comes to the location, I always think about accessibility first. You’ll want your dairy processing room to be close to where you’ll be milking your cows or goats. Trust me, the last thing you want when you’re balancing buckets of milk is to trek a mile to get to the processing area. Look for a spot that’s not only easy to access but also has good drainage for easy clean-up.

Another great tip is to consider the layout of your homestead. The processing room should complement your workflow. If you have a small barn, maybe the back corner is the perfect spot. You can design your setup so that everything flows smoothly, reducing the chances of spills and accidents. Efficiency is key!

Finally, make sure your spot has good ventilation. A must for any dairy processing room! Without proper airflow, you risk bacteria growth and funky smells. You don’t want a smelly room tainting your lovely cheese or yogurt! Aim for windows or ventilation fans that can help keep air circulating nicely.

Planning Your Space

Designing for Functionality

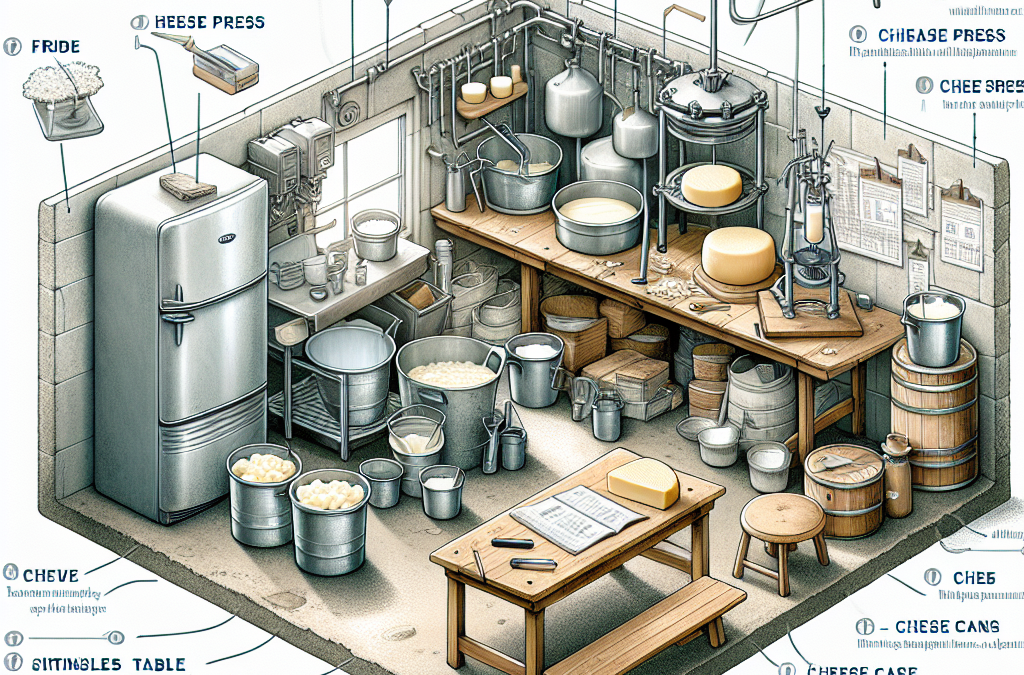

Now that you’ve got a location, it’s time to get down to the nitty-gritty of planning your space. Think about different zones within the room: one for milking, another for processing, and a storage area for your finished products. Planning helps in keeping your work organized and efficient, and it’ll definitely save you a headache later.

I like to sketch out my ideas on paper first. Drawing your design can help visualize how everything will fit together. Make sure to account for all equipment — pasteurizers, presses, and whatever else you need. More often than not, I find that I need more room than I initially thought, so be generous with your dimensions.

Also, give a thought to plumbing and electricity. You will need hot and cold water for processing and cleaning, and it’s handy to have easy access to power outlets for your equipment. Don’t skimp on these details since a good setup can save you time and effort in the long run!

Equipping the Room

Essential Tools and Supplies

Once you’ve planned your space, it’s time to equip it. I can’t stress enough how important having the right tools is! For starters, get yourself a quality pasteurizer. This little gem will ensure your milk is safe for consumption and that you can store it without worries.

Then, there’s the need for storage solutions. I highly recommend stainless steel storage tanks. They are easy to clean, resistant to corrosion, and can handle fluctuations in temperature. You’ll definitely want some durable containers to keep your products fresh and ready to go.

You’ll also need various utensils, from measuring tools to sieves for straining. It might sound trivial, but I’ve learned the hard way that having the right tools handy makes the whole process smoother. Keep your space stocked, and never run out of essential items just when you need them the most!

Maintaining Cleanliness and Hygiene

Setting Up a Cleaning Routine

Alright, let’s talk about keeping things clean. Trust me, hygiene is no joke in dairy processing. You’ll want to set a cleaning schedule that ensures all equipment and surfaces are sanitized regularly. I set aside time right after every session for a quick clean-up, so I don’t forget the gunk hiding in those corners!

Make sure to invest in cleaning supplies specifically designed for dairy equipment. They effectively kill bacteria without leaving unwanted residues. I’ve learned that using the right products not only keeps everything clean but assures the quality of my dairy products is top-notch.

Finally, consider labeling areas of your room. I’ve found that having designated zones can help keep things organized and clean. If you know where everything belongs and what each area is used for, it reduces the chances of cross-contamination and keeps your space sanitary.

Testing and Quality Control

Ensuring Product Safety and Quality

Once everything is up and running, you can’t forget about testing. I always conduct regular quality checks on my milk and dairy products. Using specific tests can determine if your product meets safety standards and is fit for consumption. Trust me, a little paranoia can go a long way in ensuring your family and customers stay safe!

It’s essential to document your processing methods and outcomes, too. This documentation helps in tracing back any issues that may arise and aids in improving your processes over time. Always be on the lookout for what could be done better.

Finally, don’t forget about taste tests! Friends and family make excellent guinea pigs for you to discover if you’re producing top-quality cheese or yogurt. Their feedback can be invaluable in refining your recipes and processes!

Frequently Asked Questions

- What equipment do I need for a homestead dairy processing room?

- You’ll need a pasteurizer, storage tanks, various utensils, and proper cleaning supplies to maintain hygiene and safety.

- How important is location for my dairy processing room?

- Location is crucial! It should be easily accessible and have proper ventilation. A good layout can enhance efficiency in your workflow.

- How often should I clean my dairy processing room?

- Establish a regular cleaning schedule after every milking session. Ensuring continuity in cleanliness is imperative to maintain safety and quality.

- What kind of documentation should I keep?

- Keep records of your processing methods, quality control tests, and any unusual findings. This will help you on your journey to producing stellar products.

- Can I use regular cleaning supplies for my dairy equipment?

- It’s best to use cleaning supplies specifically designed for dairy equipment. They’re more effective at eliminating harmful bacteria without leaving residues.

Related Content

- Hydroponics Gardening for the Homestead

- Homesteading Lifestyle: How to Live Off the Land

- Breaking Free from Codependency: The Path Towards Greater Autonomy and Freedom

- Raising Livestock at Home: Everything You Need to Know About Keeping Animals on Your Property

- From Seed to Harvest: The Complete Guide to Growing Vegetables in Your Own Backyard